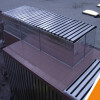

Absorptive or dissipative silencers for industrial installations

Dissipative silencers with sound-absorbing septa are manufactured to our own design and generally used in HVAC systems, in the piping for discharging the air, gas or steam into the atmosphere, and they are chosen on the basis of the noise spectrum and the noise abatement required.

Description

These silencers have a high resistance to acids and humidity and can withstand maximum working temperatures in excess of 300°C, thanks to the flameproof characteristics of all the component parts.

Their particular structure consists of septa (i.e. internal elements placed at variable intervals, generally made of high-quality, water-repellent and sulfur-free rock wool with long fibers, contained inside a steel housing), arranged longitudinally with respect to the duct, that divide and channel the air flow, facilitating the absorption of its energy. Absorptive or dissipative silencers can also be made in a cylindrical shape to suit the needs of the sound energy channel or soundproofing system, enabling considerable cost savings in the case of action being taken in a plant without any, even minimal acoustic treatment.

These silencers can also be fitted with inlet and outlet manifolds for their connection to piping, booths, industrial systems, and so on.

Their particular structure consists of septa (i.e. internal elements placed at variable intervals, generally made of high-quality, water-repellent and sulfur-free rock wool with long fibers, contained inside a steel housing), arranged longitudinally with respect to the duct, that divide and channel the air flow, facilitating the absorption of its energy. Absorptive or dissipative silencers can also be made in a cylindrical shape to suit the needs of the sound energy channel or soundproofing system, enabling considerable cost savings in the case of action being taken in a plant without any, even minimal acoustic treatment.

These silencers can also be fitted with inlet and outlet manifolds for their connection to piping, booths, industrial systems, and so on.

Technical features

- rectangular or cylindrical containment tanks made of galvanized steel sheet, complete with connection flanges, painted on request;

- longitudinal silencer septa, boxed in galvanized steel sheet and Aluzinc expanded metal mesh;

- filler made of sound-absorbing, dust-free, water-repellent and self-extinguishing materials.

- longitudinal silencer septa, boxed in galvanized steel sheet and Aluzinc expanded metal mesh;

- filler made of sound-absorbing, dust-free, water-repellent and self-extinguishing materials.

Available documents