Focus Companies

Bitron Hvac Systems (bitron Industrie Spa)

• 10.12.2013

This article is over 3 years old

Bitron HVAC Systems presents the new high efficiency Heat Exchanger

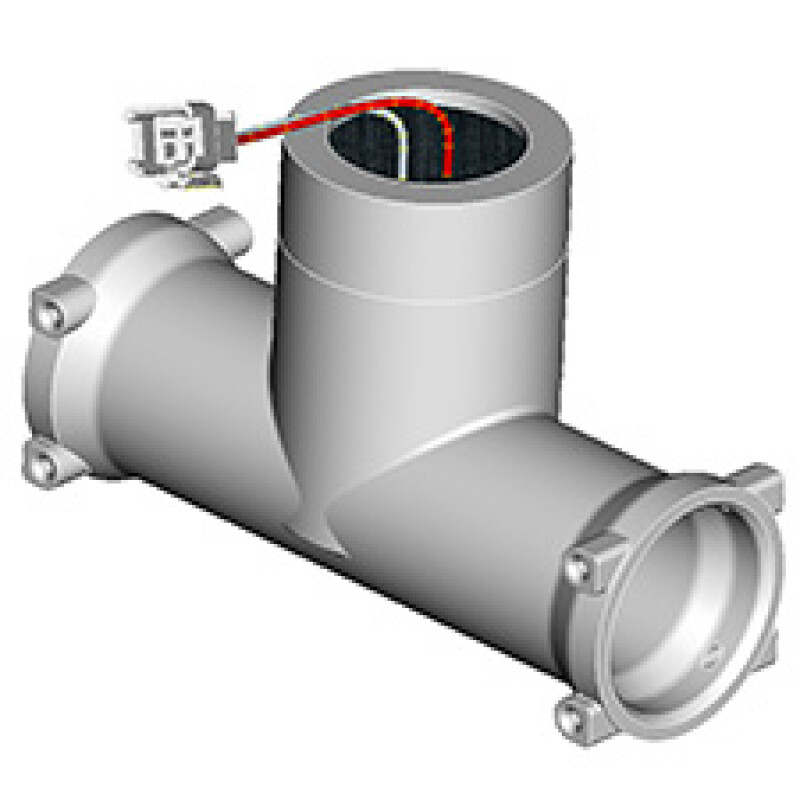

During Mostra Convegno Expocomfort 2014 in Milan, Bitron HVAC Systems will introduce to the market the new Aluminum Primary Heat Exchanger for wall-hung condensing boilers.

The Condensing primary Heat Exchanger is entirely developed and produced in Italy by Bitron in Collegno (Turin) which is the Competence and Excellence Center for BITRON HVAC Systems Division, part of the Bitron Group. The R&D team dedicated to heat exchange, fluid dynamics and efficiency is the same unique technical interface between you and us as regards hydraulics, electronics and heat exchange.

The Bitron Heat Exchanger is an innovative product in the boiler market: it is flexible and easy to customize. Flexibility is particularly obvious when looking at the exhaust pipe layout and the hydraulic connections. Both offer the advantage of easy combinations at the early stage of a new boiler design but also on existing products.

The Bitron Heat Exchanger is entirely in aluminum, a raw material that is superior to steel in terms of thermal conductivity and also lighter compared to any other material. In addition it’s also entirely recyclable. Aluminum also provides a competitive alternative to guarantee stable costs, compared to other materials affected by raw material speculation.

The Bitron Heat Exchanger also allows the standardization of the water and exhaust pipe connections. The front burner flange is also compatible with the majority of existing applications in the market. Such flexibility reduces any impact in terms of design when customers want to switch from any heat exchanger to the Bitron one.

The intelligent hook fastening system to install the Bitron Heat exchanger in the boiler represents another advantage during the first installation, for maintenance and for replacement in the field. The unique-bracket system, common to all heat exchanger sizes, differentiates the Bitron Heat Exchanger from the competition.

The Bitron Heat Exchanger also offers the possibility to use a wide variety of burners in the market. This specificity allows time saving during the development and validation of the boilers and allows many different combinations representing a unique and safe possibility.

Water connections can be customized and represent a huge benefit as the Bitron Heat exchanger can tough be connected to any Hydro block in the market allowing removal of useless brass and copper pipes.

The unique-pipe design of the Bitron Heat Exchanger differs from all the others as it has a very low pressure loss requiring a smaller pump (saves up to 0,1 bar), and ensures a lower clogging risk. The Bitron Heat Exchanger gives customers the opportunity to improve the reliability of their applications.

The innovative function of fast evacuation of the fumes in the combustion chamber allows an important reduction of CO / NOx emissions compared to past and present applications in the market. The innovative spirals and the combustion chamber volume also allow outstanding results in terms of emissions reduction.

The Bitron Heat Exchanger is an innovative product in the boiler market: it is flexible and easy to customize. Flexibility is particularly obvious when looking at the exhaust pipe layout and the hydraulic connections. Both offer the advantage of easy combinations at the early stage of a new boiler design but also on existing products.

Aluminium: a flexible and light raw material

The Bitron Heat Exchanger is entirely in aluminum, a raw material that is superior to steel in terms of thermal conductivity and also lighter compared to any other material. In addition it’s also entirely recyclable. Aluminum also provides a competitive alternative to guarantee stable costs, compared to other materials affected by raw material speculation.

Maximum compatibility

The Bitron Heat Exchanger also allows the standardization of the water and exhaust pipe connections. The front burner flange is also compatible with the majority of existing applications in the market. Such flexibility reduces any impact in terms of design when customers want to switch from any heat exchanger to the Bitron one.

Simplicity of installation

The intelligent hook fastening system to install the Bitron Heat exchanger in the boiler represents another advantage during the first installation, for maintenance and for replacement in the field. The unique-bracket system, common to all heat exchanger sizes, differentiates the Bitron Heat Exchanger from the competition.

Maximum Adaptability

The Bitron Heat Exchanger also offers the possibility to use a wide variety of burners in the market. This specificity allows time saving during the development and validation of the boilers and allows many different combinations representing a unique and safe possibility.

Customization of water connections

Water connections can be customized and represent a huge benefit as the Bitron Heat exchanger can tough be connected to any Hydro block in the market allowing removal of useless brass and copper pipes.

A unique spiral pipe design

The unique-pipe design of the Bitron Heat Exchanger differs from all the others as it has a very low pressure loss requiring a smaller pump (saves up to 0,1 bar), and ensures a lower clogging risk. The Bitron Heat Exchanger gives customers the opportunity to improve the reliability of their applications.

Emissions reduction

The innovative function of fast evacuation of the fumes in the combustion chamber allows an important reduction of CO / NOx emissions compared to past and present applications in the market. The innovative spirals and the combustion chamber volume also allow outstanding results in terms of emissions reduction.