A valve-actuator set designed to spec, for a highly innovative application in the HVAC sector

This project has been developed for a leading manufacturer of solutions that guarantee optimal energy savings in the control of temperatures in buildings, offering innovative quality products and services that ensure improved efficiency, operation and control of HVAC systems.

In this specific case, in the design of a system to maintain pressure in heating, cooling and solar circuits, the customer suffered from problems in performance due to the use of solenoid valves unsuited to the characteristics of the product itself.

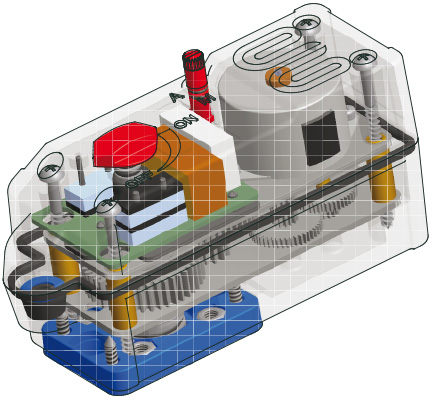

designed a solution tailored to the needs of this particular customer, producing a set made up of ball valve and actuator, adopting an approach oriented towards solving the problem in an innovative way, while guaranteeing maximum quality and durability

The design phase, entrusted to Enolgas technical engineers, was carried out by analysing the needs of the final customer and creating a dedicated product that could adapt to the specific requirements of this customer.

This innovative pressurisation and degasification system achieves improved performance in industrial and residential heating systems, optimising pressure in heat transfer fluid and eliminating the presence of air in the pipelines, to maximise performance of the system overall.

Precisely thanks to these characteristics and the need to optimise system performance, the company opted for an alternative to the solenoid valve previously used.

The need for a ball valve that guarantees a reduction in pressure drops, however needed to meet the additional need for rapid and precise control of closure via an actuator. All with an eye on costs, ever a driving factor in choice.

The technical offices of Enolgas Bonomi met the challenges of this application, drawing from their know-how in the sector of ball valves and in the production of top quality electrical actuators, producing a special model of actuator to guarantee precise control and rapid response times.

This newly designed valve/actuator set has undergone rigorous testing as requested by the customer, to simulate real application. These tests, all passed with impressive results, have enabled Enolgas to guarantee an extremely high number of duty cycles and represent one of the reasons that has led the customer to choose this component.

More specifically, the following tests were carried out:

• Life cycle of actuator, to check wear of mechanical components. The result obtained exceeds 2.5 million cycles;

• Valve resistance test (the customer requested at least 1 million cycles);

• Test on response to control pulses

The choice of an Enolgas product as a system component is thanks to:

• Reduced pressure drops ensured by the ball valves in place of solenoid valves;

• The characteristics of speed and control of the motor;

• The strength and resistance over time of our valve/actuator set with respect to the solenoid valves;

• The price/quality ratio offered.

In particular, the electrical circuit diagram developed for this specific motor (H-BRIDGE) enables rapid and precise adjustments, making it extremely versatile, combining the ON-OFF (open-close) with the control function.

All within a package that is both compact (practical for those installing it in machinery or confined spaces) and strong (the actuator comes with IP65 protection rating).