Focus Companies

Rdz

• 11.01.2013

This article is over 3 years old

Underfloor heating: 3 centimetres are enough

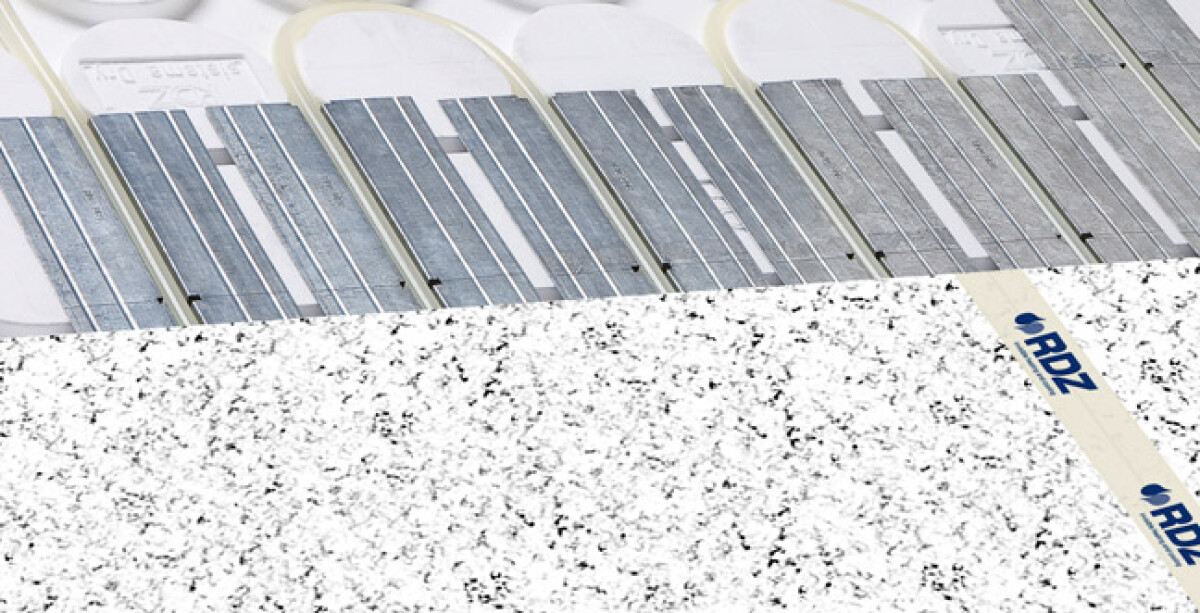

In additional to the traditional underfloor heating systems, RDZ offers DRY-TECH. It is a dry solution, which is particularly suitable for those applications where installation thickness and weight shall be reduced, such as in renovated buildings, lofts or on old floors, especially in houses.

The specific aspect of this system is the absence of concrete, which implies several advantages. Firstly, this makes it possible to save several centimetres of thickness, thus guaranteeing very low thermal inertia and rapid functioning. Secondly, it reduces installation timing, since the walking surface is immediately ready, and you do not need to wait for the concrete to dry up.

The main components of this system are:

• Dry-Tech panel with reliefs is made of sintered polystyrene, produced in conformity with UNI EN 13163. It is a waterproof panel with a closed-cell structure, which has high mechanical resistance. Thermal conductivity is 0.035 W/(m-K), while total thickness is 25 mm. These panels have a moulded surface with special grooves so that the thermal diffusers can be fitted into them to hold the pipes;

• Dry-Tech panel with reliefs is made of sintered polystyrene, produced in conformity with UNI EN 13163. It is a waterproof panel with a closed-cell structure, which has high mechanical resistance. Thermal conductivity is 0.035 W/(m-K), while total thickness is 25 mm. These panels have a moulded surface with special grooves so that the thermal diffusers can be fitted into them to hold the pipes;

• Thermal diffusers are made of zinc-plated steel, thickness 0.4 mm. They are used to contain RDZ Tech pipe and act as heat transfer;

• RDZ Tech pipe is used to distribute hot and cold water. This pipe (diam. 14 mm and thickness 2 mm) is made of high-density electro-physically cross-linked polyethylene with the anti-oxygen barrier between the Pe-xc layer and an outside layer made of PE, which ensures further protection during installation in the building site. The layers are combined thanks to a special glue. This pipe is produced according to UNI EN ISO 21003/2 and DIN 4726, guaranteeing even and stable cross-links and constant characteristics over time.

• Weight distribution layer is made of synthetic fibres, laminated on both sides, with compressive strength of 590 kN/m2, thermal conductivity of 0.042 W/(m.K), and size 1200x800x4 mm. The plates shall be combined to one another through an adhesive tape in order to create an even surface. Ceramic flooring shall be stuck by using a specific cement glue mixed with water and elastic latex; wooden flooring shall be laid as floating covering.

Considering a very compact solution with only 3 centimetres of thickness, RDZ offers a special system with low thermal inertia, easy installation, immediately ready walking surface also for those applications where traditional radiant systems cannot be used.

The specific aspect of this system is the absence of concrete, which implies several advantages. Firstly, this makes it possible to save several centimetres of thickness, thus guaranteeing very low thermal inertia and rapid functioning. Secondly, it reduces installation timing, since the walking surface is immediately ready, and you do not need to wait for the concrete to dry up.

The main components of this system are:

• Dry-Tech panel with reliefs is made of sintered polystyrene, produced in conformity with UNI EN 13163. It is a waterproof panel with a closed-cell structure, which has high mechanical resistance. Thermal conductivity is 0.035 W/(m-K), while total thickness is 25 mm. These panels have a moulded surface with special grooves so that the thermal diffusers can be fitted into them to hold the pipes;

• Dry-Tech panel with reliefs is made of sintered polystyrene, produced in conformity with UNI EN 13163. It is a waterproof panel with a closed-cell structure, which has high mechanical resistance. Thermal conductivity is 0.035 W/(m-K), while total thickness is 25 mm. These panels have a moulded surface with special grooves so that the thermal diffusers can be fitted into them to hold the pipes;• Thermal diffusers are made of zinc-plated steel, thickness 0.4 mm. They are used to contain RDZ Tech pipe and act as heat transfer;

• RDZ Tech pipe is used to distribute hot and cold water. This pipe (diam. 14 mm and thickness 2 mm) is made of high-density electro-physically cross-linked polyethylene with the anti-oxygen barrier between the Pe-xc layer and an outside layer made of PE, which ensures further protection during installation in the building site. The layers are combined thanks to a special glue. This pipe is produced according to UNI EN ISO 21003/2 and DIN 4726, guaranteeing even and stable cross-links and constant characteristics over time.

• Weight distribution layer is made of synthetic fibres, laminated on both sides, with compressive strength of 590 kN/m2, thermal conductivity of 0.042 W/(m.K), and size 1200x800x4 mm. The plates shall be combined to one another through an adhesive tape in order to create an even surface. Ceramic flooring shall be stuck by using a specific cement glue mixed with water and elastic latex; wooden flooring shall be laid as floating covering.

Considering a very compact solution with only 3 centimetres of thickness, RDZ offers a special system with low thermal inertia, easy installation, immediately ready walking surface also for those applications where traditional radiant systems cannot be used.